Wall Support and Foundation Stabilization

Challenge

After noticing drywall cracks around the interior of his home, Lane called TFS. We sent our specialist, Lakon Tucker, out for a complimentary inspection.

While completing the inspection, Lakon noticed that one of the walls in the crawl space of the home was bowing inward. When learning of this, the homeowner wanted a solution that would stabilize his home’s foundation and provide support for the wall in his crawl space to prevent it from bowing any farther.

Solution

Upon assessment, our specialist recommended our CarbonArmor system from Supportworks to provide support to the bowing wall, and the use of our galvanized steel Push Piers to stabilize the foundation of the home.

CarbonArmor consists of fiber-reinforced polymers and is ten times stronger than steel yet flexible enough to tightly contour to walls and provide added support. Our Push Piers are the best solution in our industry to permanently stabilize the foundation of a home. This specific project required 2 Carbon Armor straps placed on the inside of the bowing wall and 3 Push Piers inside the crawl space.

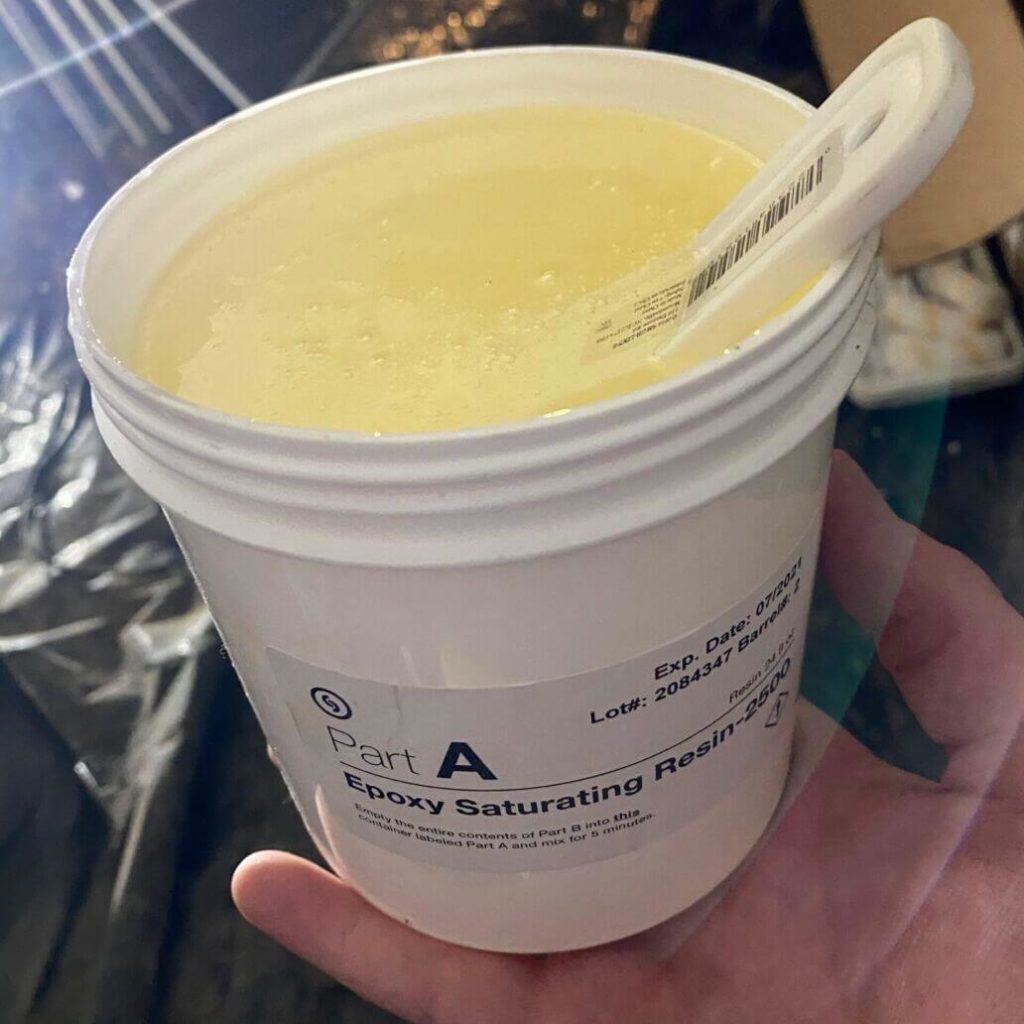

Our production crew arrived on the scene and benchmarked the locations of the CarbonArmor and Push Piers. Once identified, the prep work began. The area where the CarbonArmor was installed was first ground down, and all cracks were filled with epoxy paste to ensure they were as smooth as possible.

The crew dug to the footer of the home and prepped it for the pier brackets by grinding down a flat surface in the locations where each pier was installed. Once the wall and footer were prepped, it was time to mix the epoxy resin and cut the CarbonArmor material to the right size. The resin was then generously coated on both the wall and CarbonArmor strips and each strip was installed. Another layer of epoxy resin was rolled over the straps after they were installed.

The crew added another strip of CarbonArmor horizontally across the other two straps to provide further support for the wall. After the CarbonArmor was installed, it was time to move onto the piers.

Brackets were placed below the footer where it had been ground down, and the starter tube was placed through. A hydraulic press was then placed on top of the bracket and used to push the first piece of pipe into the ground. Our crew continued to push the pipe until bedrock or load-bearing strata were found. This took about two 3.5-foot sections on each bracket.

After each pier reached the bedrock, the crew cut off the excess pipe and caped each one. The home was stabilized, and the crew cleaned up by backfilling the hole they had dug and replacing the vapor barrier which was covering the entirety of the crawl space. Lane was very pleased with our wall support and foundation stabilization work and thanked us for the peace of mind that we have provided him!

Project Summary

Specialist

Lakon Tucker

Team Leader

Kaiden Hall

Materials Used

Push Piers (3), CarbonArmor (2)